Use numerical simulation to ensure

your product or project is compliant with the requirements

Engineering teams across multiple industries partner with TENSOR to ensure their product designs are compliant with client requirements. We use advanced virtual prototyping based on accurate numerical models, drastically reducing the need for physical testing and compressing time-to-market

Numerical simulation experts with 26 years experience in CAE Software and Services

Trusted by companies in 5 countries worldwide

when to contact usThe Problem

Have your Product Design and R&D engineering team ever been in any of the following situations?

Expertise

Costs

Testing

Issues

Incompatibilities

how to solveThe Solution

Ensure your products meet all requirements and exceed client expectations with our expert CAE (Computer-Aided Engineering) capabilities and robust virtual prototyping:

Expertise

Costs

Testing

Issues

Incompatibilities

when to contact usThe Problem

Have your Product Design and R&D engineering team ever been in any of the following situations?

Expertise

Your product is innovative and customized but you lack a standard design or internal expertise to guide its development

Costs

The costs of physically testing all design choices is prohibitive. Still, you aim for the best-in-class product and you need to optimize the cost ratio

Testing

Prototype fails during experimental verification and testing, but going back to the drawing board is very expensive

Issues

Unexpected operational issues with potentially large negative impact

Incompatibilities

Retrofitting challenges caused by incompatibilities with existing equipment

/how to solveThe Solution

Ensure your products meet all requirements and exceed client expectations with our expert CAE (Computer-Aided Engineering) capabilities and robust virtual prototyping:

Expertise

Use advanced simulation tools to perform comprehensive digital testing of design choices

Costs

Develop a simulation process that validates adaptability and compatibility with existing systems

Testing

Implement a virtual prototyping system that allows for extensive scenario testing

Issues

Adopt a simulation framework that models the product’s design and operational conditions

Incompatibilities

Integrate simulation revealed data into your design process to anticipate and rectify potential failures before they occur

Ensure your products meet all requirements

aboutCAE

Our proficiency in Computer-Aided Engineering (CAE) and our capacity for engineering analysis ensures that your end product aligns with all project specifications, fulfilling your requirements and expectations completely:

Faster Iterations: Speed up the design cycle by identifying potential issues early, allowing for quick iterations and refinements.

Enhanced Innovation: Use simulation tools to explore more design variations and innovative solutions safely in a virtual environment.

Risk Reduction: Minimize the risks associated with product failure by ensuring all design aspects are validated before production.

Cost Efficiency: Reduce the costs associated with physical testing and late-stage redesigns by catching and correcting flaws during the virtual prototyping phase.

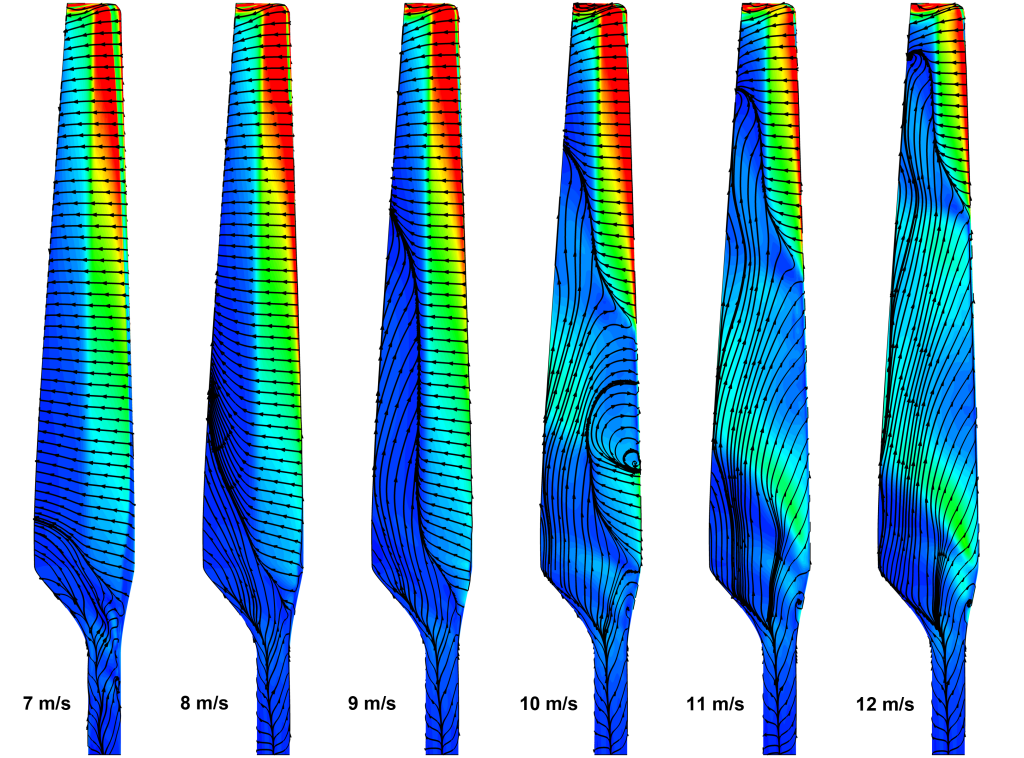

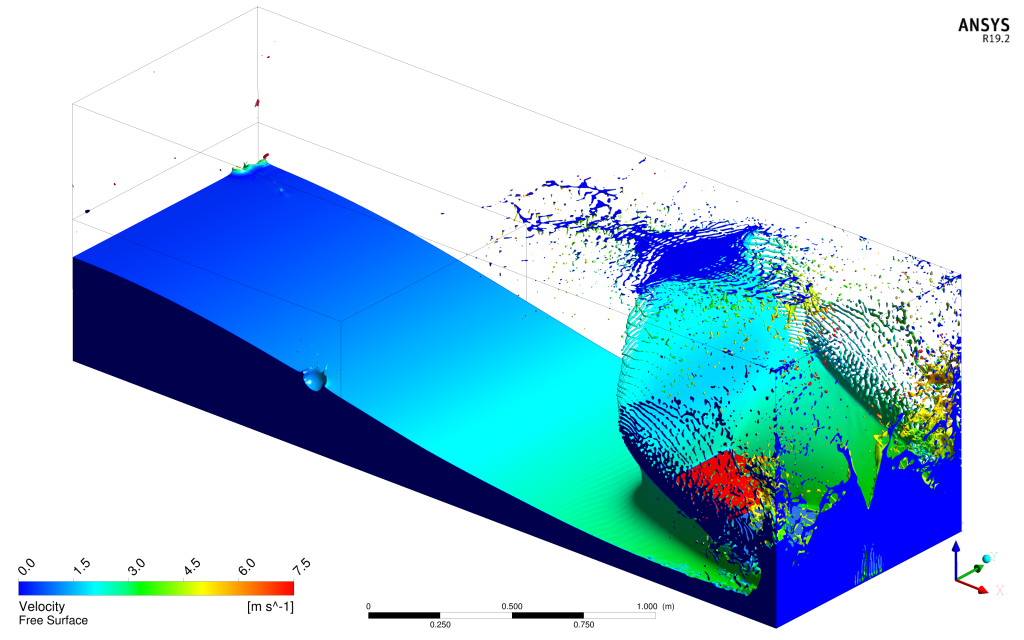

aboutCFD

We conduct CFD analyses and leverage our expertise to provide you with informed guidance for design, product development, or issue resolution. Our CFD simulations propel your projects forward, offering exceptional insights and optimizing design efficiency, product performance and safety, ultimately saving time and resources.

Optimized Fluid Dynamics: We provide deep insights into fluid flow behavior and thermal management, crucial for optimizing product functionality and efficiency.

Streamlined Production: By applying CFD to simulate real-world conditions early in the design process, we help reducing failures due to fluid dynamics or thermal issues.

Improved Product Quality: Advanced CFD simulations ensure that products are optimized for performance, reducing failures due to fluid dynamics or thermal issues..

Enhanced Regulatory Compliance: Our analysis ensures products meet stringent industry standards related to environmental and safety regulations, reducing the risk of compliance issues.

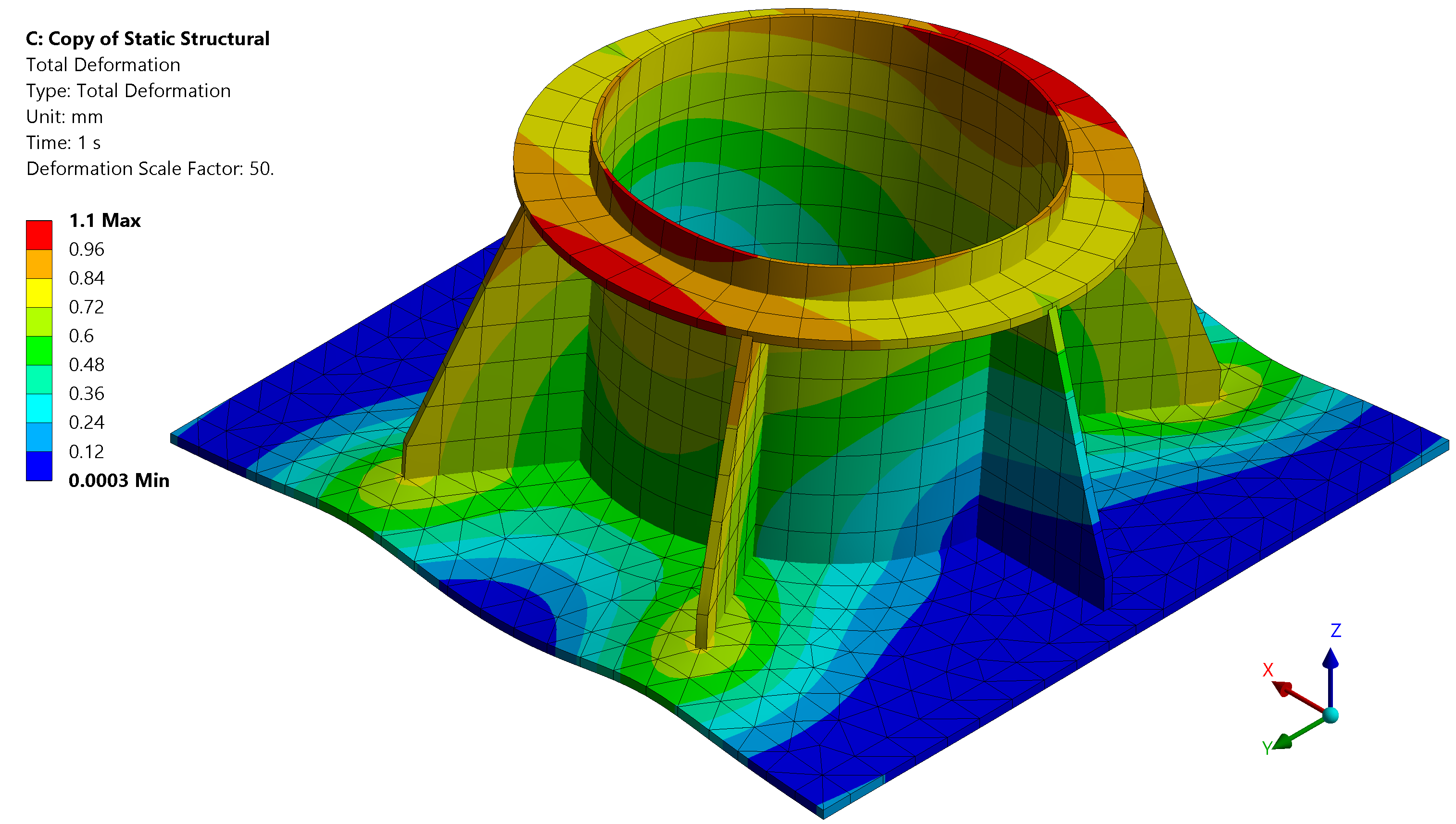

aboutFEA

Through FEA simulations, we verify thermal stresses and structural integrity of your products, to ensure alignment to client specifications, also offering comprehensive analysis and recommendations if necessary.

Informed Decision-Making: Our FEA analyses provide vital insights into product structural responses and stress distributions across diverse loading scenarios.

Optimized Design Solutions: Leveraging FEA capabilities, we assess and refine initial and revised designs to maximize structural efficiency and safety.

Understanding Failure: FEA simulation helps understanding the failure before or after it occurs.

Proactive Problem Solving: Early detection of potential structural or thermal vulnerabilities enables proactive rectification, mitigating risks before prototype development and conserving valuable time and resources.

100% Confidence in product compliance

We guarantee your final product aligns precisely with project requirements, meeting all customer needs and real-world standards.

Cost savings and efficiency

Decreased time-to-market through quality assurance measures and streamlined engineering solutions, and gain immediate and long-term financial benefits.

Comprehensive support and reassurance

Strengthened brand reputation

testimonialsHear what our customers say about our solutions

Excellent team with highly qualified professionals that are ready to help you, not only to explain or describe the products they sell, but to actively participate in the development of your simulation. They developed for us, a simulation of the current distribution in a pair of positive and negatine plates in a lead acid battery, that helped us to evaluate the best geometry for our positive grids (current collectors)

Electronics packaging activities include mandatory modeling and simulation. The education and training activities require solid knowledge to shape the proper future engineers of the electronics packaging domain and not only.

From this perspective, to have the possibility to be in contact with experts of the CFD & FEA Simulation Services, like the TENSOR team represent a great advantage. During common activities we could appreciate the competence and availability of the TENSOR team.

The CFD and FEA services provided by Tensor accurately model complex

systems behavior, providing a key contribution for first time success.

The quality of the CFD analysis services is at the top level worldwide; the scientific/technical approach is always at the state-of-the art level, correlated with the resources available in the practical projects. (translated)

services

Our Services

CFD Simulation

FEA Simulation

Software Distribution

Training & Support

downloadOur Brochure

servicesThe Process

1. Discovery Meeting

Introductory meeting to understand your project requirements and goals.

2. Numerical Simulation

Creating the simulated digital environment to prepare the simulation. We can perform virtual prototyping for an entire product or just for a part of the product’s design process.

Preprocessing

Preparing geometric models and assembly drawings, performing meshing for numerical analysis, and establishing initial and boundary conditions to mirror real-world scenarios.

The Simulation Process

Conducting the simulation based on predefined setups, closely supervising its progress to ensure it aligns with expectations, and adjusting parameters as necessary with minimal intervention.

Post Processing

Extracting and analyzing the numerical results from the simulation, identifying and addressing discrepancies, and providing actionable recommendations for potential improvements or corrective actions.

Iterative Loop

Repeating the simulation process as needed to refine outcomes, address dysfunctions, or adjust to varying input data, ensuring continuous optimization and accuracy for meeting project requirements.